Corrosion With Aluminium & Stainless Steel Products

Electrolysis / Galvanic Action

Corrosion can occur between dissimilar metals such as in Aluminium & Stainless Steel Security Doors & Screens, despite the manufacturers best attempts to keep the metals apart. This is often referred to as Electrolysis or Galvanic Action, the process is exacerbated by the presence of 'Salt Air' i.e. from oceans, salt water lakes, swimming pools or in certain circumstances industrial fallout. This action destroys the Aluminium, it will generally present as a white or light brown coloured powder, the Aluminium will swell, bubble, become brittle, the Stainless Steel may also become brittle and paint will flake off.

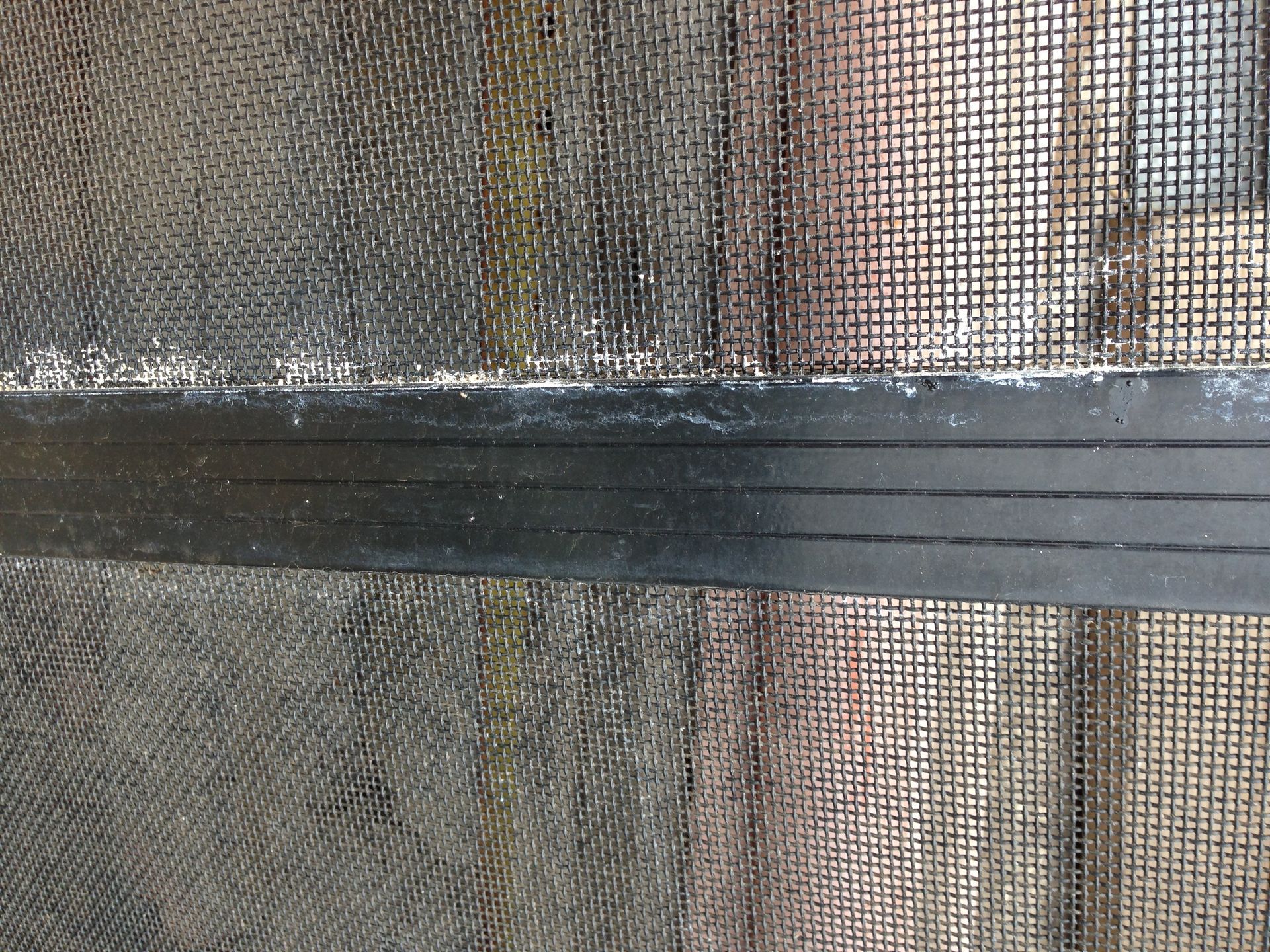

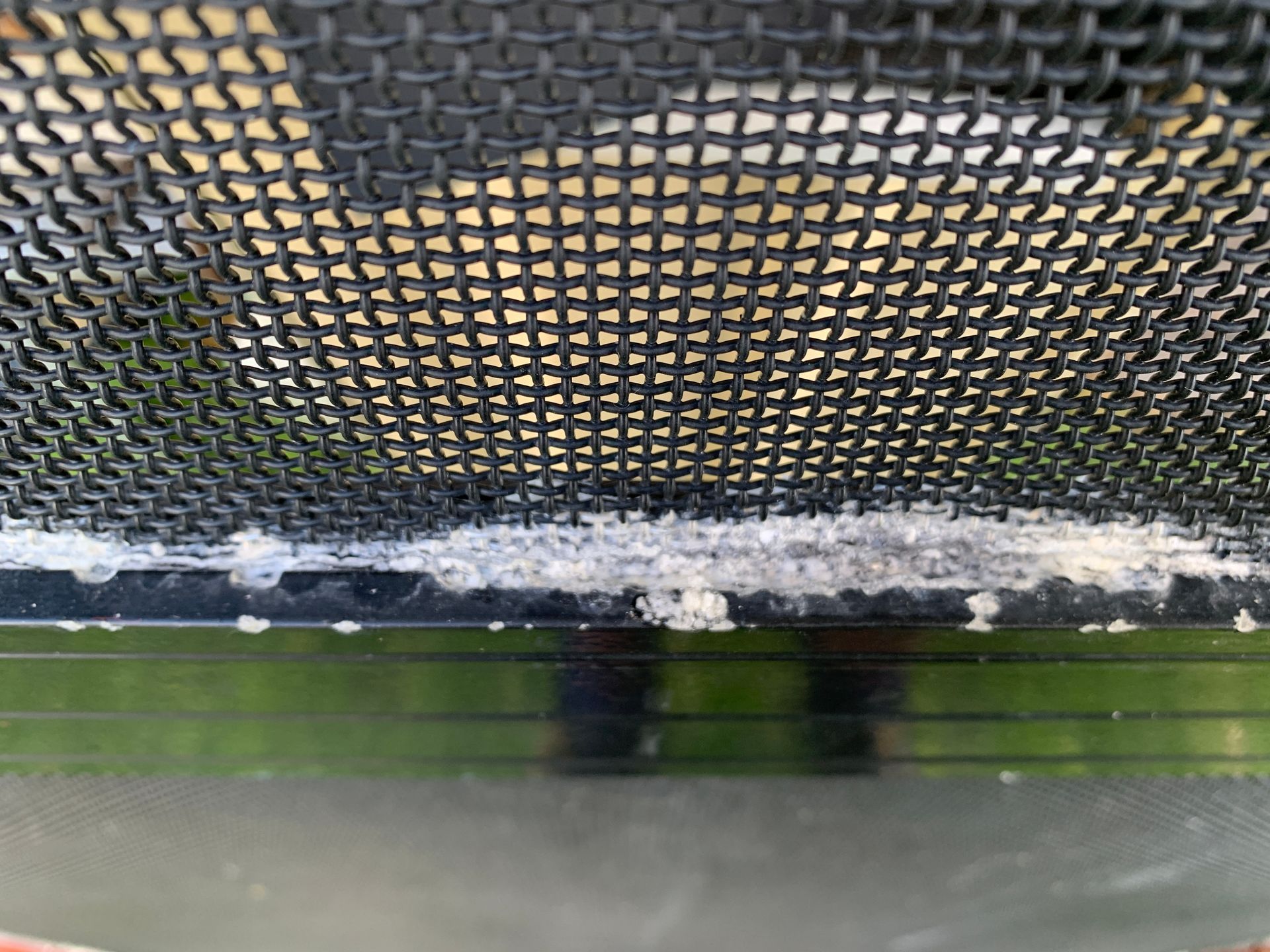

The process is salt air / moisture accumulates on the security grill or fly mesh and gravitates downwards to the crossbar or bottom of the screen / door. The salt and moisture bridge any barrier or protection that has been put there and the Galvanic action takes place. Generally you will not see any evidence of corrosion on the tops of doors.

What is the Time Frame you ask, this basically depends on you proximity to the source e.g. ocean generally the closer you are the higher the risk, it also depends on the aspect of the house as one side can present with heavy corrosion and the other aspect will have virtually none. Having said that I have seen Fly Screens deteriorate in 3 to 5 years.

Can you prevent or slow the process of this from occurring. Yes, it is possible, also if you read the warranty they all generally state that you will void your warranty unless you wash your product down in mild soapy water up to twice a month depending on your proximity to the ocean or as described above. This action should prolong the life of the product as it washes off the salt from the grill or mesh.

General Corrosion

Corrosion can also occur with prolonged exposure to the salt atmosphere decaying the Aluminium, this occurs in normal Fly Screens with fibreglass mesh, Security Doors and other Aluminium products, making them impossible to repair.

This can also occur in Aluminium Fly Screens that have a Stainless Steel fly mesh normally either 304 or Marine grade 316, these are normally required for fire zones with a BAL rating above BAL29. Shown below with blistering on the frame and powder in the spline channel.

Vision Mesh displayed in some photos below designed for a one way effect, will deteriorate quite quickly in a salt environment developing white powdery spots everywhere.

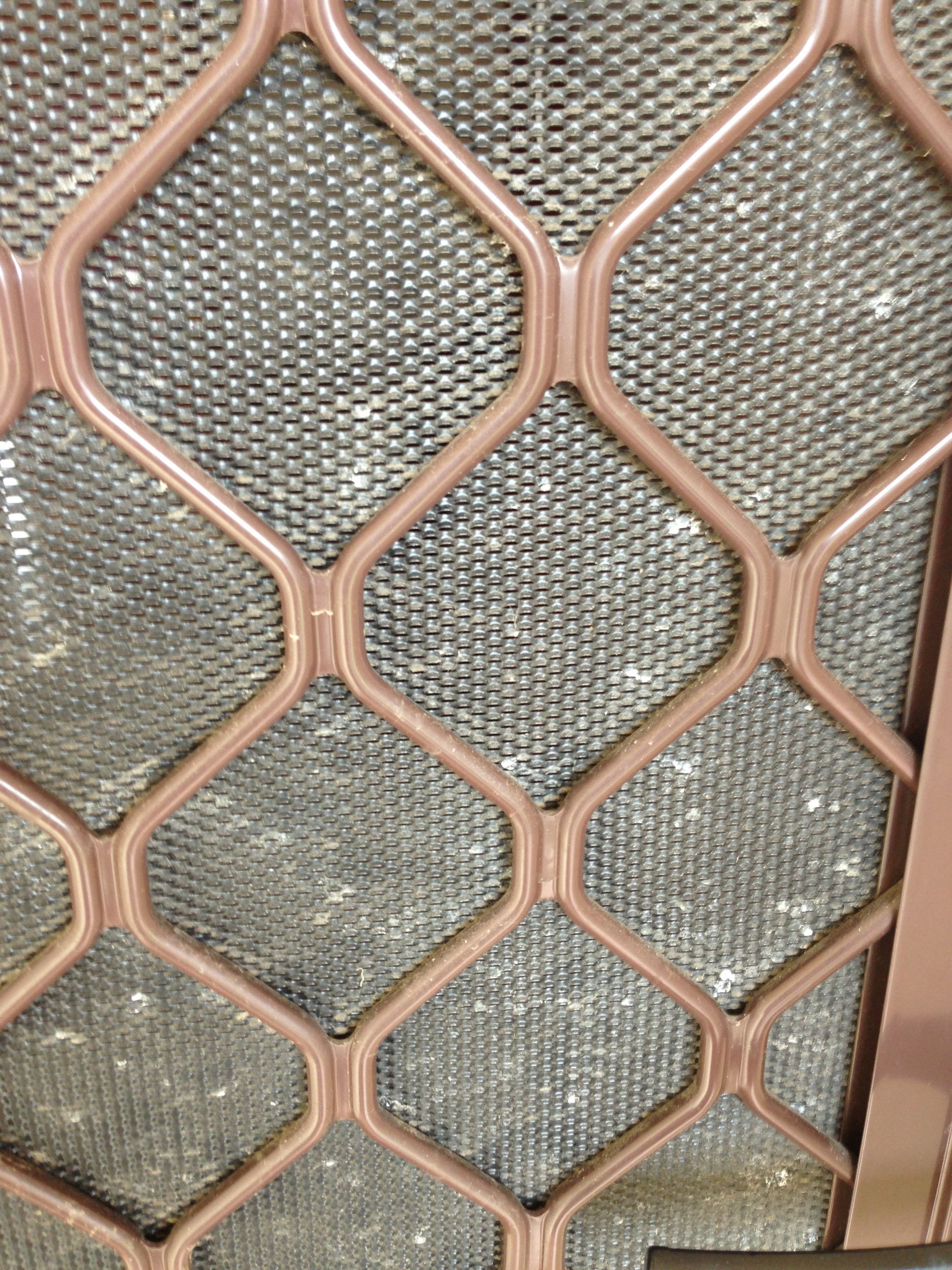

Cast Aluminium Issues.

Cast Aluminium also has issues with paint delaminating from the metal, this generally will occur after 5years or so and i believe the cause is the de-gasing process when the Aluminium is cast.

I have seen attempts to repaint these grills, the paint generally will delaminate.

QUICK LINKS

CONTACT INFORMATION

Phone: 0411 104 817

Email: john.rayner52@gmail.com

Address: Unit 2/203 Dudley Rd,

Whitebridge, NSW, 2290

ABN: 27095906344